The Swedish AIM-120B's, carried by the 'Gripen', are designated as Rb 99. The B-model incorporates a new digital processor, erasable programmable read only memory, and five major electronic unit hardware chassis upgrades. The AIM-120B missile was the result of the two block AMRAAM Producibility Enhancement Program. blast fragmentation warhead has not been disclosed. At closer ranges AMRAAM guides itself all the way using its own radar, freeing the launch aircraft to engage other targets. Upon intercept an active-radar proximity fuze detonates the 40-pound high-explosive warhead to destroy the target. With its sophisticated avionics, high closing speed, and excellent end-game maneuverability, chances of escape from AMRAAM are minimal. In case the target tries to protect itself with active jamming, AMRAAMs seeker switches to a medium-PRF "home-on-jam" mode. Since this seeker uses its own active radar (unlike the Sparrow), it does not require the launch aircraft to illuminate the target or to track the target.

It transitions to a self-guiding terminal mode when the target is within range of its own monopulse radar set, operating in high-PRF mode.

In long-range engagements AMRAAM heads for the target using inertial guidance and receives updated target information via data link from the launch aircraft. Data Link (for mid-course guidance update).Inertial Reference Unit, Target Detector and fuze.The propulsion section consists of an advanced solid-fuel rocket motor to achieve a speed of Mach 4 and a range in excess of 30 miles.

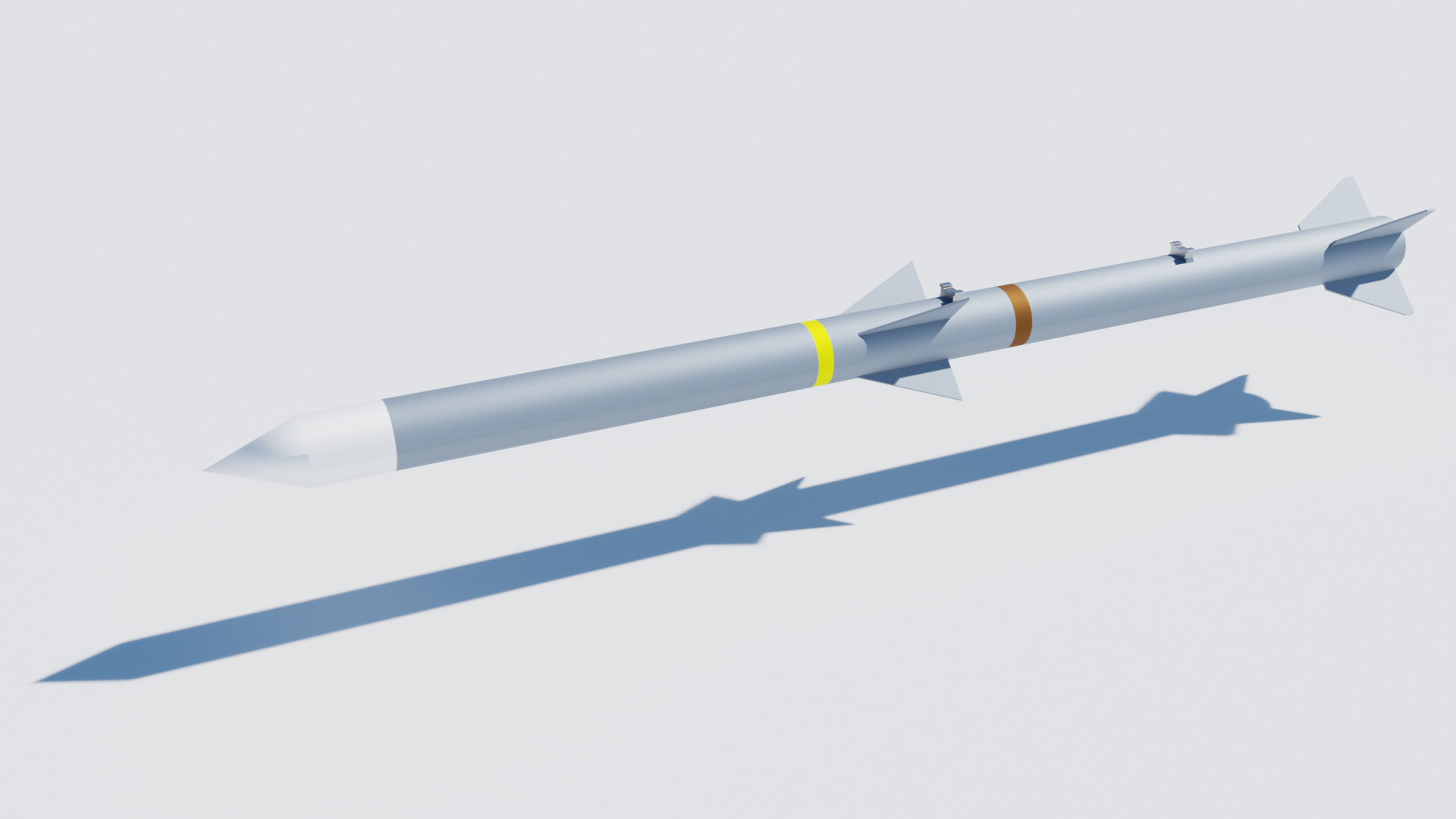

Navigation, autopilot, radar, datalink, fuzing, sequencing, and self-test functions are allhandled by a single 30MHz microprocessor. The guidance section features an active X-band radar terminal seeker using a highpower solid-state transmitter with a low-sidelobe, wide-gimbal antenna, and a built-in radio-frequency processor. The airframe is divided into four major sections: guidance, warhead, propulsion and control. The AMRAAM is housed in a light-weight structure of steel and titanium. Full-rate production of the missile was approved in April 1992, marking Milestone III. The F-16 followed in January 1992, and the Navy in October 1993. In September 1991, IOC (Initial Operational Capability) was achieved for the AMRAAM on USAF F-15 aircraft. The subsequent FY 1988 order for 630 missiles was split 55/45 with the biggest share for Hughes. Of the initial 180 missile, USD $537.4 million (four times higher than estimated) order, Raytheon produced 75 and Hughes 105 rounds. Production is split (under Caesar's 'Devide and Conquer' motto) between two contractors, Hughes and Rate. By this time, some of the problems were solved and low-rate initial production ( LRIP) was approved for FY 1987. The fact that no European counterpart for the AMRAAM exists, is due to an MoU (Memorandum of Understanding) signed by West Germany and the UK, assigning AMRAAM to the USA and ASRAAM (Advanced Short Range Air to Air Missile) to Europe.īy 1985, AMRAAM was in serious trouble: huge cost overruns and delays meant that not a single test round was fired in a hostile ECM-environment until October 1986. Mugu, with the missile proving itself against increasingly tougher targets. The AMRAAM program entered FSD (Full Scale Development) in September 1982, and test firing of the missile started in that same year at Holloman AFB and NAS Pt.

FIRING AIM 120 MISSILE WITHOUT LOCKING TARGET FULL

At the end of 1981, after only 6 missiles were fired (3 each), Hughes Aircraft & Missile Systems Group was picked over Raytheon to build 94 test missiles, with an option for 924 full production missiles. Both contractors received a contract for ten prototype missiles each, which were to be fired from F-14, F-15 and F-16 aircraft. (USAF photo)The original list of five proposals was narrowed down to 2 in February 1979. AIM-120 launch sequence by an USAF F-16A.

0 kommentar(er)

0 kommentar(er)